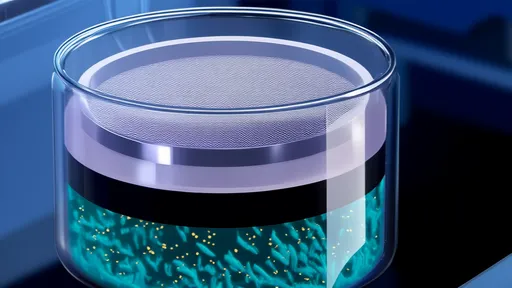

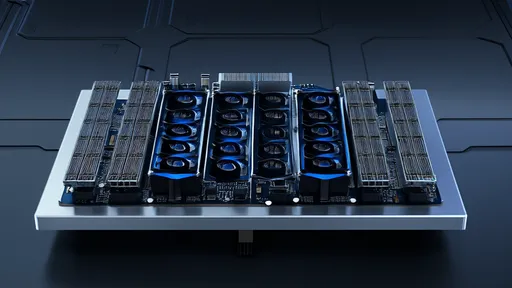

Immersion cooling has emerged as a revolutionary approach in thermal management, particularly for high-density computing applications like data centers and cryptocurrency mining. At the heart of this technology lies the immersion cooling fluid, a specialized dielectric liquid that directly contacts electronic components to dissipate heat. While much attention is paid to thermal conductivity and viscosity, the chemical stability of these fluids often becomes the unsung hero determining long-term system reliability.

The chemical stability of immersion cooling fluids refers to their resistance to decomposition or reaction when exposed to heat, electrical stress, or materials within the cooling system. Unlike traditional air cooling, where inert gases pose minimal reactivity concerns, liquid immersion creates an intimate molecular interaction between the coolant and every surface it touches. This makes the fluid's inertness not just preferable but absolutely critical for preventing corrosion, swelling of elastomers, or the formation of conductive byproducts that could compromise electrical insulation.

Most commercial immersion cooling fluids today fall into two broad chemical categories: synthetic hydrocarbons and fluorinated fluids. Synthetic hydrocarbons, often based on polyalphaolefins (PAOs) or alkylated aromatics, offer excellent thermal transfer at relatively low cost but face inherent stability limitations. The carbon-hydrogen bonds in these molecules can gradually break down when subjected to prolonged operation above 100°C, especially in the presence of catalytic metal surfaces like copper or aluminum. This degradation typically manifests as increased viscosity, sludge formation, or in worst cases, the production of acidic compounds that attack sensitive components.

Fluorinated fluids, particularly those using perfluoropolyether (PFPE) chemistry, represent the gold standard for chemical stability in harsh environments. The carbon-fluorine bond ranks among the strongest in organic chemistry, granting these fluids exceptional resistance to thermal, oxidative, and electrical degradation. Data center operators have documented PFPE-based coolants maintaining stable properties through five years of continuous operation at temperatures exceeding 125°C. However, this performance comes at a steep premium - fluorinated fluids often cost 10-20 times more than their hydrocarbon counterparts, making them economically viable only for mission-critical applications.

Material compatibility testing reveals surprising nuances in fluid stability that aren't apparent from chemical structure alone. Certain fluorinated fluids, while exceptionally stable themselves, can actually accelerate the degradation of specific elastomers used in gaskets and seals through a phenomenon called extractive swelling. The fluid gradually dissolves plasticizers and other additives from polymers, causing them to shrink and lose sealing pressure. Leading fluid manufacturers now provide comprehensive compatibility matrices detailing tested combinations of coolants with hundreds of common manufacturing materials.

Oxidative stability presents another critical dimension, particularly for single-phase immersion systems where the fluid remains in constant contact with atmospheric oxygen. Accelerated aging tests simulate years of service by bubbling air through heated coolant samples while monitoring acid number and dielectric strength. Premium-grade fluids incorporate radical scavengers and oxidation inhibitors that dramatically extend fluid life, though these additives themselves must remain stable to avoid becoming contamination sources. The most advanced formulations now achieve oxidation induction times exceeding 5,000 hours at 150°C in standardized testing protocols.

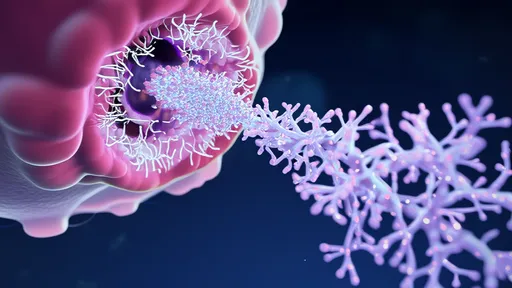

Electrical stress represents perhaps the most unique stability challenge in immersion cooling. Unlike transformer oils that primarily experience AC voltages, immersion coolants for electronics must withstand complex electric fields combining high-frequency switching noise with DC biases. Partial discharge activity can initiate fluid decomposition through a process called electrical treeing, where micro-channels of degraded fluid propagate through the dielectric like branching lightning. Fluids with high electron affinity, typically those containing aromatic rings or heteroatoms, demonstrate superior resistance to this form of degradation.

The pursuit of biodegradable immersion coolants has introduced new stability considerations. Natural ester fluids derived from seed oils offer compelling environmental profiles but face inherent chemical stability limitations due to ester hydrolysis and unsaturated bond oxidation. Recent breakthroughs in additive packages have enabled next-generation bio-based fluids to achieve usable lifespans, though still falling short of synthetic alternatives. One innovative approach grafts stabilizing functional groups onto triglyceride molecules, creating hybrid fluids that combine renewable sourcing with hydrocarbon-like stability.

Real-world operational data continues to reshape understanding of long-term fluid stability. Unexpected interactions have emerged in large-scale deployments, such as the gradual accumulation of dissolved solder flux residues altering coolant properties, or the catalytic effect of certain conformal coatings accelerating fluid breakdown. These findings underscore that true chemical stability must be evaluated not just for pristine fluids, but for complete operational ecosystems including all materials, contaminants, and operational conditions the coolant will encounter.

Looking ahead, the immersion cooling industry appears poised for a stability paradigm shift with the development of self-monitoring smart fluids. These advanced formulations incorporate molecular probes that change fluorescent properties in response to degradation byproducts, enabling real-time fluid health assessment without sampling. Early implementations suggest such technologies could transform maintenance strategies from scheduled changes to condition-based interventions, potentially doubling effective fluid service life while preventing unexpected failures.

As immersion cooling expands beyond niche applications into mainstream data center operations, the chemical stability of cooling fluids will increasingly dictate total cost of ownership and system reliability. The next generation of fluids will need to balance unprecedented stability requirements with growing environmental regulations and cost pressures - a challenge that will require innovations not just in chemistry, but in system design, monitoring technologies, and lifecycle management approaches.

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025